Glass drilling is a technology that has been revolutionized by the development of the green laser. This enables the production of laser machines that can drill holes and shapes in glass quickly and precisely. Customers who are thinking about investing in this technology need to calculate the cycle time of the goods they produce. The drilling speed depends on several factors, such as the glass thickness, the shape of the area to be drilled and whether the shape fits into the scanner field of 50×50 mm. In addition, factors such as glass color and coating can also influence the drilling speed. By understanding these factors, customers can determine the feasibility of investing in this technology. In this article, we will delve into the world of green laser technology and explore how it can revolutionize the glass drilling process.

The basic principles of the drilling process

Understanding the fundamentals of the drilling process is critical to predict what is technically possible and to troubleshoot problems. Here is a brief explanation.

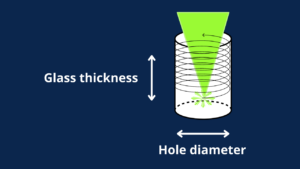

The process consists of focusing a laser beam on the surface of the glass, which then penetrates to the bottom, where the ablation process begins. When drilling a hole, the laser beam follows a spiral upward path that gradually ablates the glass until the center piece falls out and a hole is created. This process is highly controlled and precise to ensure accuracy in the end product. The area that is unloaded consists of 0.2 – 0.3 mm.

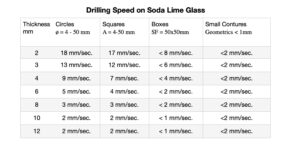

To assess the feasibility of a new investment, companies need to determine the cycle time for their manufactured product. Discussions about our laser technology usually focus on creating holes or shapes in glass. Take a look at the following schedule to understand the process of calculating the cycle time:

Our scanner works in a 50×50 mm field in which the laser shows competitive drilling times. As an example, consider the white goods industry, where we may need to drill an 11 mm hole in 4 mm thick glass.

To calculate the cycle time, we divide the circumference of the hole by the drilling speed. Referring to the table above, we find that the drilling speed for a circle in 4 mm thick glass is 9 seconds.

With this information, the equation is:

(11 mm x 3.14(pi))/9 = 3.837 seconds.

This drilling speed is generally considered acceptable in the white goods industry.

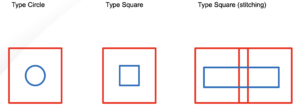

Our machines can perform shape cut-outs on any geometry within the scan field, with only a slight reduction in speed. However, if the shape extends beyond the scan field, our cutting speed is significantly reduced due to the need for a stitching method.

With this method, the laser has to resume the cut at the exact point where it stopped at the 50 mm edge of the scan field, which results in a loss of cutting speed.

Conclusion

We hope that we have been able to give you a good impression of the drilling speed of our green laser technology. With this basic information, you should be able to form an opinion on your existing facility and decide whether our technology could be a viable application for your next investment. If you require further support or information, please do not hesitate to contact us. We will be happy to advise you on your application and introduce you to the world of #lasermeetsglass.