How does the process of cutting glass with a CO2 laser work?

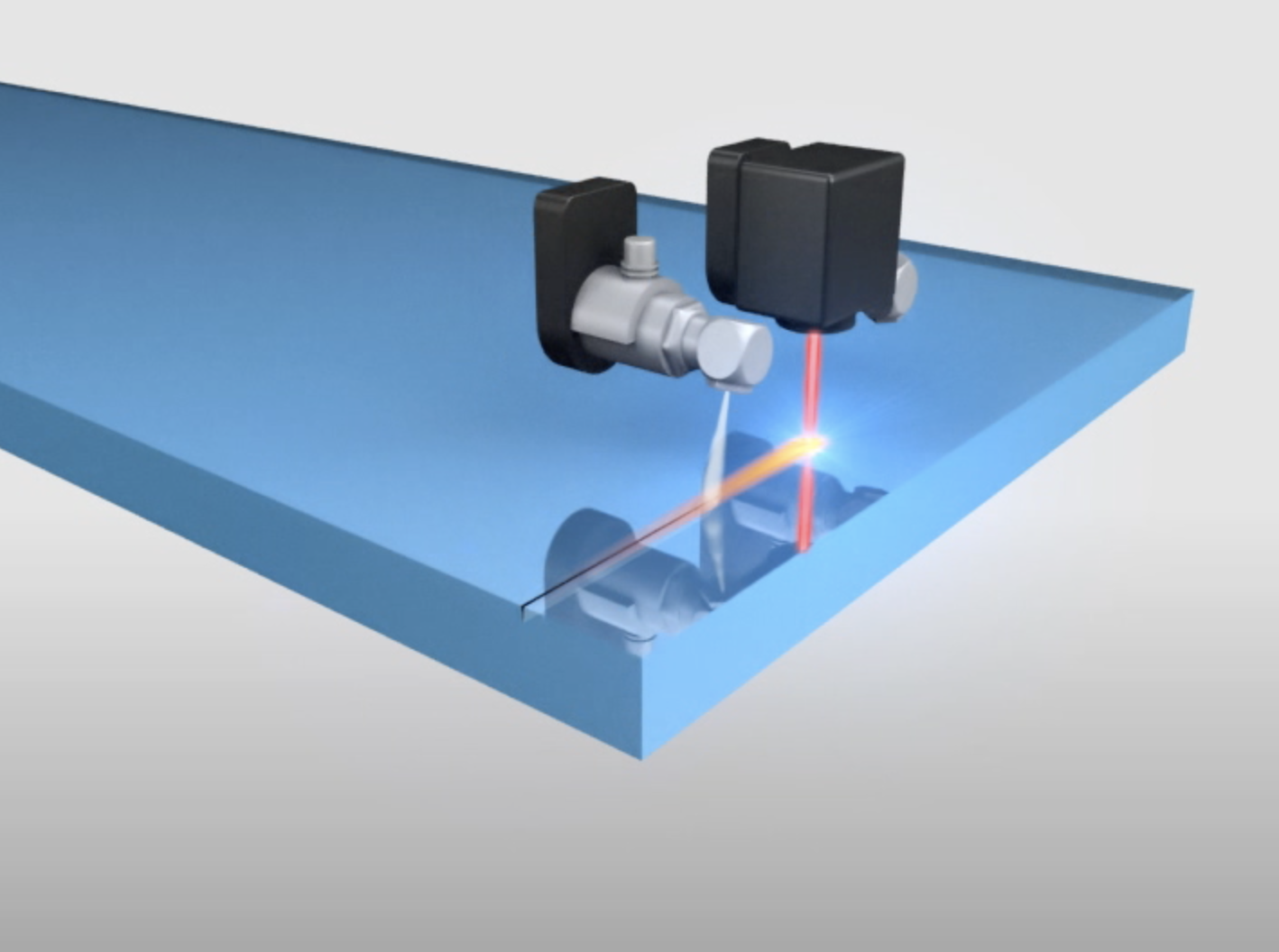

The CO2 laser cutting process begins with a focused laser beam that precisely heats the glass. A stream of cold air or an air-liquid mixture is then introduced, creating thermal stress and causing controlled cracks in the glass. The glass is separated by a careful breaking process, resulting in edges of optical quality.

Can the CO2 laser only cut straight lines or is it also possible to cut shapes?

The CO2 laser is designed for straight cuts. For cutting shapes, we recommend using a green laser or conventional cutting tools.

Can the CO2 laser cut all types of glass?

The CO2 laser can cut all types of glass with a coefficient of thermal expansion of more than 3 × 10-⁶ K-¹.

What is the thinnest and thickest glass thickness that can be cut with a CO2 laser?

The CO2 laser can cut glass with thicknesses from 0.03 mm to 2 mm.

How fast is the CO2 laser?

Depending on the glass thickness, the cutting speed can reach up to 600 mm per second.

What are the advantages of CO2 laser cutting compared to traditional glass cutting methods?

CO2 laser cutting offers several advantages over traditional methods:

- Precision: It prevents chipping and ensures clean and precise cuts.

- Optical edge quality: Smooth edges are produced that often require no additional finishing.

- Efficiency: Minimizes material waste due to the narrow beam width.

- Versatility: Enables complex designs and precise cuts.

- Cost efficiency: Improved efficiency and superior end product quality make it a cost-effective option.

Can I temper glass that has been cut with a CO2 laser?

Yes, glass that has been cut with a CO2 laser can be tempered without any problems.

What are the typical applications of CO2 laser-cut glass?

CO2 laser-cut glass is used in applications that require high edge strength and clean edges, such as optical devices, architectural elements and precision glass components. The process is particularly valued for producing edges without micro-cracks, which ensures optimum light transmission.

Who would benefit from using the CO2 laser to cut glass?

The CO2 laser is ideal for anyone looking for high edge strength and precision, making it suitable for industries that require superior edge quality and complex designs.